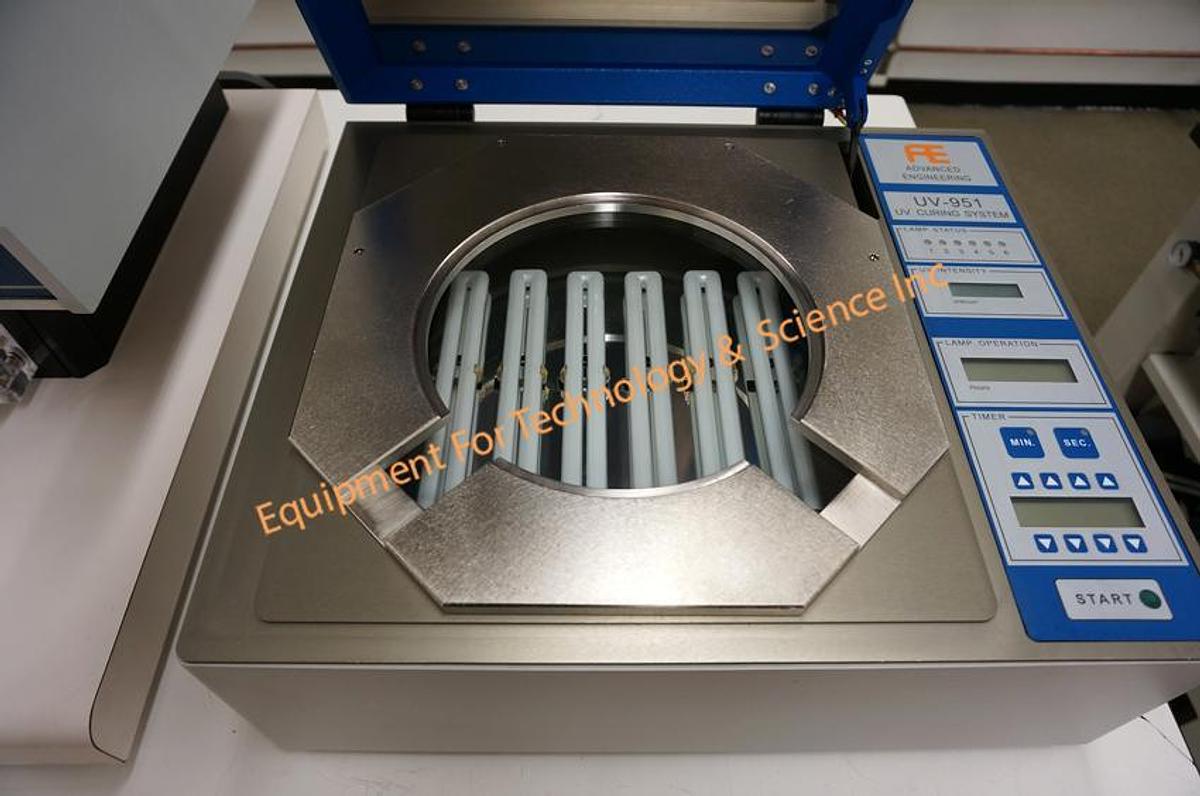

Advanced Engineering 951UV Dicing Tape Cure

Advanced Engineering 951UV Dicing Tape Cure

$4,950 (USD)

Description

UV curing system for reducing the adhesive strength of UV sensitive dicing tapes, effective UV wavelength 365nm, holds wafers up to 200mm, ozone free UV irradiation source, timer, UV-intensity meter, lamp hour and status indicator, 110v,

see www.eshal.com model UV-946 for more information.

Single-frame, up to 8" wafers, UV dosage control, user-friendly digital display, lamp life indicator, lamp ON and UV intensity monitoring.

Safe, Ozone-free UV Irradiation - Uses optimized wavelength for UV curing process. Low-pressure mercury vapor lamps do not require special cooling or nitrogen systems to counteract harmful ozone emissions. The UV-956 provides a safe operating environment and economical utility requirements.

The UV-956 is the most advanced system in its class, with built-in UV irradiation Dosage Control for controlled, repeatable UV tape curing for single-frame processing. The UV-956's digital control panel displays all process parameters on-line. The system handles all standard wafer/frame combinations up to 8" on its 300mm diameter UV irradiation window.

Wafer/Frame size: All standard sizes, up to 8".

Throughput: 50 frames/hr.*

Power: 100 W (peak).

(20 x 48.5 x 40.5 cm).

Weight: 44 lbs. (20 kg).

Test conditions: UV tape curing energy required = 200mJ/cm2 with silicon wafer.

Specifications

| Stock Number | 1080 |

| Sort | 0 |