Features and Specifications

Gasonics/IPC 9104 Ash/Etch system

12"(dia) x 20"(D) quartz barrel

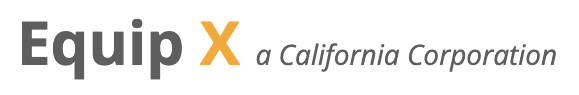

soft pumping and purge valving

low particulate design

2ea mass flow gas inputs with VCR fittings

all SS plumbing,

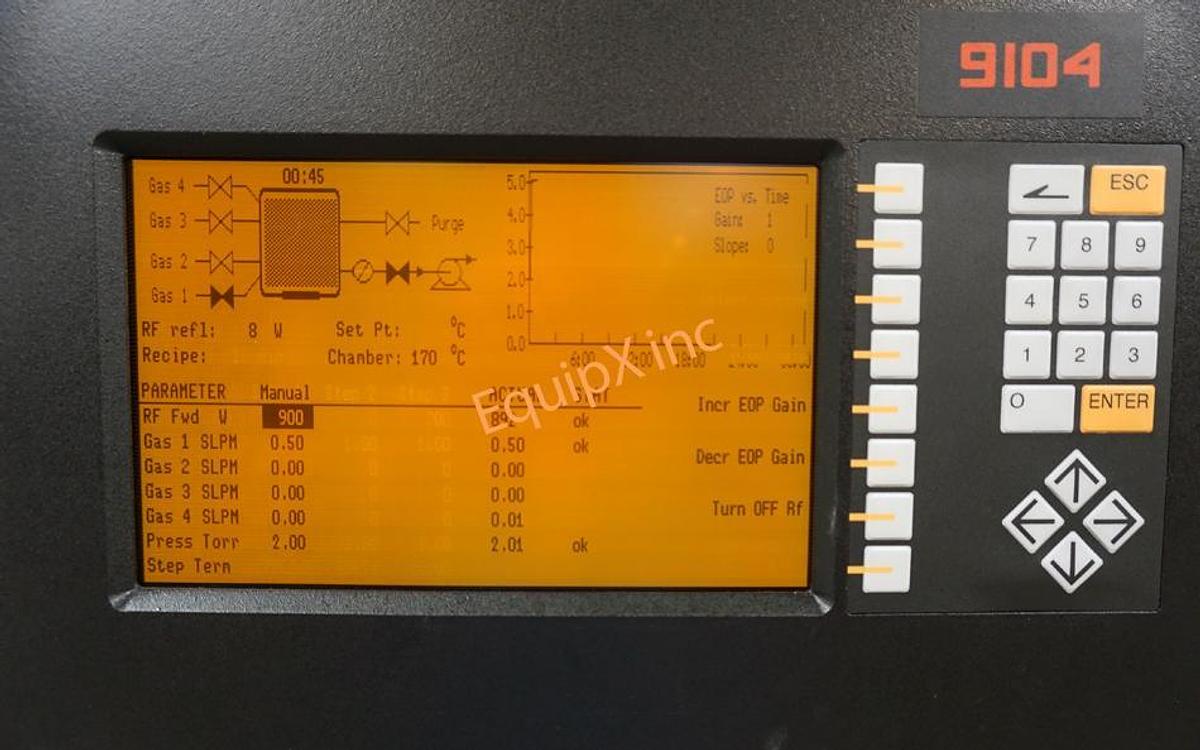

multi channel/single board computer controlled, with floppy storage

temperature monitor

ENI OEM 12B 1250W RF Generator

Wafer Size: 4", 6", 8" capability

Capacity: 50 8" wafers, 50-75 6" wafers, 100 4" wafers.Â

Chamber: Quartz, compatible with fluorinated chemistry. 12" diameter x 20" deep. External RF electrodes.

RF Generator: 1250 watt 13.56 MHz air cooled with automatic impedance matching network. Water cooled optional.

Process Pressure: Approx. 120 - 2000 mtorr.

Stainless Steel Plumbing.

Temperature Monitor: Quartz-coated thermocouple located in the process chamber.

Display: Color 12.1" touch screen for control and monitoring of process parameters, automatic recipes, or manual plasma treatments.

Four user specified gases, with 500 sccm Stainless Steel MFCs come standard with an optional 3rd and/or 4th gas channel available.

Power Requirements: 208 - 240 volts, 3 phase, 50/60 Hz 5 wire "wye".

A NEMA-12 wall mounting enclosure with locking handle contains the AC power control for the asher, power supply, and pump, allows for a single source drop for the complete system.

CE Certified.