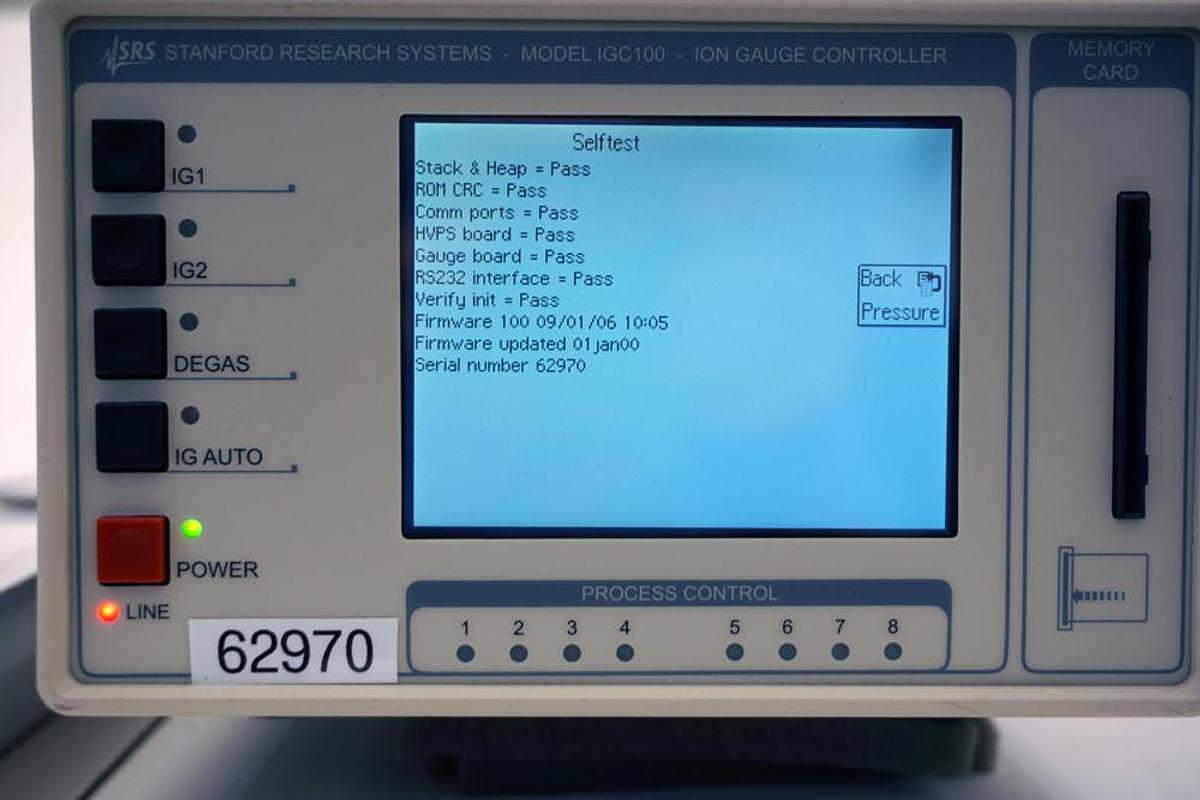

Stanford Research IGC-100 Ion gauge controller (NEW UNUSED STILL IN MANUFACTURER'S BOX)

Stanford Research IGC-100 Ion gauge controller (NEW UNUSED STILL IN MANUFACTURER'S BOX)

$1,800 (USD)

Description

| The IGC100 is a high-accuracy vacuum gauge controller that offers pressure measurement and process automation never before available in a single instrument. It measures pressure from Bayard-Alpert ionization gauges, convection-enhanced Pirani gauges,and capacitance manometers providing uninterrupted pressure readings from 1000 Torr to UHV. |

IGC100 Ion Gauge Controller

The IGC100 is a high-accuracy vacuum gauge controller that offers pressure measurement and process automation never before available in a single instrument. It measures pressure from Bayard-Alpert ionization gauges, convection-enhanced Pirani gauges, and capacitance manometers providing uninterrupted pressure readings from 1000 Torr to UHV.

The IGC100 has a touchscreen display that can present data in a variety of formats including pressure versus time curves. There are built-in relays for process control, and several multipurpose input/output ports. The IGC100 is also fully web-ready. Now you can monitor and control your vacuum system from the lab, your home, or anywhere in the world.

Accurate Measurements

The IGC100 is designed to be a highly accurate, stable controller. Its low noise, autoranging electrometer delivers high accuracy pressure readings into the UHV range. A low-noise, direct current (DC) supply powers the filament and establishes the emission current. The IGC100’s precision electronics eliminate controller-to-controller variations and the measurement uncertainties (up to 15 %) associated with traditional instruments.

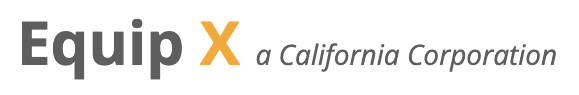

Graphical Touchscreen Displa

The IGC100 has a large, back-lit LCD touchscreen display—new to vacuum gauge controllers. The instrument shows large numeric readings from each gauge (easily read from across the room), and can also display readings in bar graph or trend format. The screen is updated twice a second and results are presented in units of Torr, mbar, bar, Pa or microns. The IGC100 also displays pressure versus time curves (chart recordings), allowing you to follow pump down and venting cycles and to keep track of your vacuum system’s performance.

IGC100 data is continuously logged into memory. There is a real-time clock with date for precise time stamps. In addition to pressure readings, you can log the ADC voltages and relay activity. Data can be viewed on the IGC100 or downloaded to your computer for further analysis.

Fully Web-Ready

The IGC100 has an optional Ethernet interface with embedded web-server hardware that makes your controller fully web-ready. All you need is an internet connection and you can monitor and control your vacuum system from anywhere in the world. Just log on to the internet and enter the IP address of your controller—it’s really that simple!

Useful I/O Ports

The IGC100 has four auxiliary analog input/output ports. When configured as inputs, the ports can be monitored on the front panel or read through the GPIB, RS-232 or web interfaces, and can be used for a variety of applications. For instance, they might be used to monitor the pressure of a capacitance manometer, measure pump speed, record temperature from a turbo pump controller, or monitor a mass flow controller.

The ports can also be configured as analog outputs with a voltage range of ±12 VDC, and can be used to send control voltages to other devices.

Powerful Process Control

The IGC100 does more than simply measure pressure. It can also be an eight channel process controller. There are eight relays, with corresponding TTL outputs, that can be used to control your vacuum system. They can be set by gauge pressure, status conditions (gauge on/off, filament on/off, etc.), the system clock, the analog I/O ports, or TTL input signals. The relays and TTL outputs can also be manually controlled from the front panel, and the status of all eight channels can be displayed.

Additionally, there are twelve dedicated TTL inputs for triggering functions like gauge on/off, filament on/off, degas, ion gauge lockout, etc. All process control events are time stamped and recorded in memory, and can be viewed at any time. User-programmable audible alarms and text messages can provide advance warning of potential problems.

Gauge Auto-Start

The IGC100 can be set to automatically turn on an ion gauge once a Pirani gauge has reached a preset pressure level. If a UHV Pirani gauge is used in the same high-vacuum chamber as the ion gauge, you can make uninterrupted pressure measurements from atmosphere to UHV. In the event of overpressure, the IGC100’s built-in filament protection algorithm, with user-programmable set point, immediately turns off your gauge filament.

Easy Operation

Despite its many features, the IGC100 is easy to use. The menu based interface is intuitive, and parameter entry is quick and simple. And of course, there is interactive help for all functions of the instrument. There are dedicated front-panel buttons for filament emission, degas, and filament auto-start, and LEDs indicate their status. The IGC100 is compatible with virtually all Bayard-Alpert ion gauges including glass tubulated, nude, nude-UHV, STABIL_ION®, and MICRO_ION®. You can select from a variety of standard gauge configurations or program your own.

You can also assign a location name to each gauge, which is then displayed on the front panel of the unit. No more messy, confusing stickers on the face of your instrument. There are no DIP switches, trim pots or thumbwheel adjustments in the IGC100—you’ll never need to open the box.

A sensor on/off function has been added so you can shut down your Pirani gauges in the presence of flammable gases without having to physically disconnect them from the controller.

Password protection is provided to keep casual users from accidentally altering important parameters.

A high-level command set, along with an RS-232 and optional GPIB interface, allows you to fully control the IGC100 from your computer.

SRS Gauges

SRS supplies a wide range of hot-cathode ionization gauges. These include tubulated and nude designs with a variety of mounting options, and a choice of tungsten (W) or thoriated-iridium (ThO2/Ir) filaments.

We also offer a convection-enhanced Pirani gauge (PG108). PG108 gauges offer a measurement range that extends from 1000 Torr to 10-4 Torr. With its all-metal seal, the PG108 is the only convection-enhanced Pirani gauge that can be operated directly in UHV environments, and baked to 250 °C without any disassembly. The PG108 is calibrated for N2, Ar and air. The IGC100 controller is also compatible with CONVECTRON® and HPS™Series 317 convection-enhanced Pirani gauges.

IGC100 Specifications | |

Operation | |

| Pressure range | 1000 Torr to UHV (<10-11) |

| Compatible gauges | Bayard-Alpert type ionization gauges, convection-enhanced Pirani gauges, capacitance manometers (0 to 10 VDC linear output) |

| Display | |

| Type | Back-lit, touchscreen LCD (4.7") |

| Resolution | 320 × 240 pixels |

| Modes | Numeric, bar graph, P vs. T |

| Units | Torr, mbar, bar, Pa and micron |

| Numeric resolution | 3-digit mantissa plus exponent |

| Update rate | 2 samples per second |

| Dual Pirani gauge | Simultaneous readout of two Pirani gauges (std.) |

| Auto-Start | Use PG1 or PG2 to automatically turn IG1 or IG2 on/off when pressure goes through user-defined level. |

Electrical (20 °C to 30 °C) | |

| Electron emission current | |

| Range | 10 µA to 12 mA |

| Stabilization | Electronically controlled |

| Accuracy | ±1 % of setting |

| Anode | |

| Potential | +180 VDC |

| Accuracy | ±0.3 % of setting |

| Filament | |

| Potential | +30 VDC |

| Accuracy | ±0.3 % of setting |

| Filament power (max.) | 7 ADC, 7 VDC |

| Degas | |

| Mode | Electron bombardment |

| Power | 1 to 75 W, adjusted in 1 watt steps |

| Time | 1 to 30 minute, adjusted in 1 minute steps |

| Anode potential | 500 VDC |

| Emission current | 2 to 150 mA |

| Display | Approximate pressure, degas power and remaining time |

| Electrometer | |

| Accuracy | 1 % of reading |

| Zero drift | 0.4 pA |

| Analog I/O | |

| Ports | 4 configurable analog ports |

| Range | ±12 VDC |

| Resolution | 14-bit (In), 12-bit (Out) |

| Update rate | 2 Hz |

| Connector | BNC |

Vacuum Ionization Gauge | |

| Gauge type | Bayard-Alpert type ionization gauges including glass tubulated (std. and broad-range), nude, nude-UHV, STABIL_ION®, MICRO_ION®. Supports tungsten and thoriated-iridium filaments. |

| Pressure range | 10-11 to 10-1 Torr |

| Lower limit | X-ray limit of Bayard-Alpert gauge |

| Upper limit | Maximum operating pressure specified by gauge manufacturer |

| Pressure calculation | From sensitivity constant or full range calibration curve |

| Sensitivity constant | 0.1/Torr to 100/Torr |

| Filament selection | Fil 1, Fil 2, or both |

| Overpressure protection | Programmable trip points, auto-start protection |

| Analog output | Log, 1 V/decade, 1 to 10 V w/ fault and off indication |

Convection-Enhanced Pirani Gauge | |

| Gauge type | PG108 convection-enhanced Pirani gauges, CONVECTRON® and HPSTM Series 317 convection-enhanced Pirani gauges. |

| Pressure range | 999 to 10-3 Torr. Lower pressure limit extends to 10-4 Torr w/ zero adjustment. |

| Gas type calibration | Direct readings for air, N2 and Ar. Menu driven zero and atmospheric adjustments. |

| Analog output | Log, 1V/decade, 1 to 8 V |

Capacitance Manometer | |

| Number of gauges | Simultaneous readout of up to four capacitance manometers using the auxiliary inputs. |

| Auxiliary power output | ±15 VDC, 100 mA (for CM power) |

Process Control (opt.) | |

| Number of channels | 8 channels with programmable setpoint, polarity, hysteresis, delay, audio signal and text messages. All channels can be manually operated from front panel. |

| Process variables | Pressure (any gauge), voltage (I/O ports), time (internal clock), TTL and gauge status. |

| Relays | 8 relays, SPDT, form C, 5A/250VAC/30VDC, resistive load |

| TTL control | 8 TTL inputs and 8 TTL outputs (active low, opto-isolated) corresponding to relays |

| Additional inputs | 12 opto-isolated TTL inputs corresponding to: Remote Enable, IG1 on/off, IG2 on/off, Degas on/off, Fil 1/Fil 2 select, both Fil select, IG lockout, IG Control keypad lockout, PG1 on/off, PG2 on/off, data logging time reset, touchscreen enable/disable |

General | |

| Interfaces | RS-232 (std.), GPIB (opt.) |

| Power | 90 to 264 VAC, 47 to 63 Hz, 240 W |

| Operating temp. | 0 °C to 40 °C, non-condensing |

| Weight / dimensions | 15 lbs., 8.5" ×5.25" × 16" (WHL) |

| Warranty | One year parts and labor on defects in materials and workmanship |

Specifications

| Stock Number | 3780 |

| Sort | 0 |