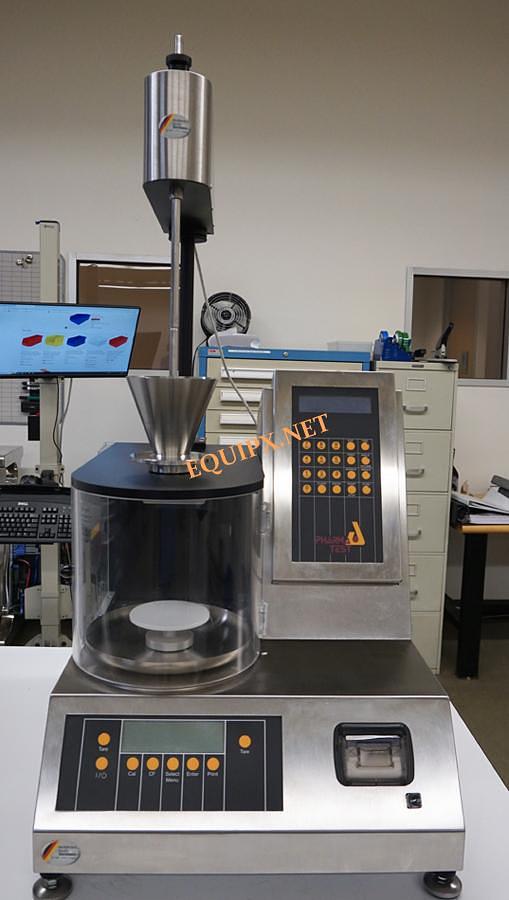

Pharma Test PTG-S4 Auto Powder Characterization System

Pharma Test PTG-S4 Auto Powder Characterization System

$23,500 (USD)

Description

Most Informative Flowability Tester in the Market

The automated PTG-S4 powder testing system is used to measure the flow behaviour of granules and powders in compliance with the current EP <2.9.36/17> and USP <1174> pharmacopoeia as well as with the international ISO 4324 standards. This instrument is suitable for testing powderflow time, measureing the cone angle (angle of repose) of the collected powder mound and printing a powder flow chart. While measuring the weight, the powder cone density, the powder cone volume as well as the EP “flowability” results are calculated. The ”flowability” means measuring the flow time of 100g of sample through a specified pouring nozzle. The PTG-S4 is equipped with a built-in analytical balance cell with a range of 1 – 350mg and an accuracy of 1.0 mg. Furthermore the instrument features and integrated dust protection bonnet and a built-in printer.

Why Measure the Flow Properties of Powders?

It has been estimated that over 50% of the materials used in all industrial applications were at some stage in a powder form. These powders need to be transported, injected, propelled and be able to pass through various process stages before they achieve their final form. This final form may be a tablet, a suspension or indeed a powder formulation. The need to be able to measure, control or test for reproducible powder flow has been well established in many industrial applications.

Powder flow characteristics are important for:

In processes, which rely on powder and / or powder, mix integrity, the need to have the correct powder flow characteristics is paramount. These powder mixes have to be formulated, mixed and certainly transported. Transportation, even over small distances an easily lead to classification of sorts such that “fines” may drop out and alter the particle size distribution and hence the flow characteristics.

Operation Principle

The design is compliant to the current EP <2.9.36/17> and USP <1174> monographs as well as to the ISO 4324 (12/83) standard. A conical stainless steel funnel which can be equipped with different pouring nozzles (ranging from 4 – 25mm) takes the sample to be tested. The built-in analytical balance cell is mounted inside the instrument housing and holds the product collecting dish. The PTG-ER electrical stirrer attached to the main instrument may be used for those powders which do not flow easily due to the high percentage of fine particles.

Now available: small POM product funnel and dish for just 10g of sample.

Features

Advantages

Specifications

| Stock Number | 4582 |

| Sort | 0 |