Royce Instruments Autoplacer MP300 for wafers up to 200mm (2016)

Royce Instruments Autoplacer MP300 for wafers up to 200mm (2016)

$34,900 (USD)

Description

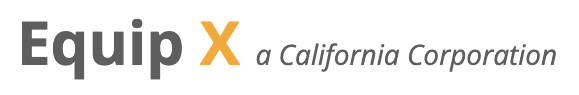

Royce Instruments MP300 Autoplacer

Manufacture Date 2016

Serial # 1006516

Maximum 200mm wafer (motorized xy stage has 8x8 travel)

includes 3 die pickup assemblies

All manuals and software included

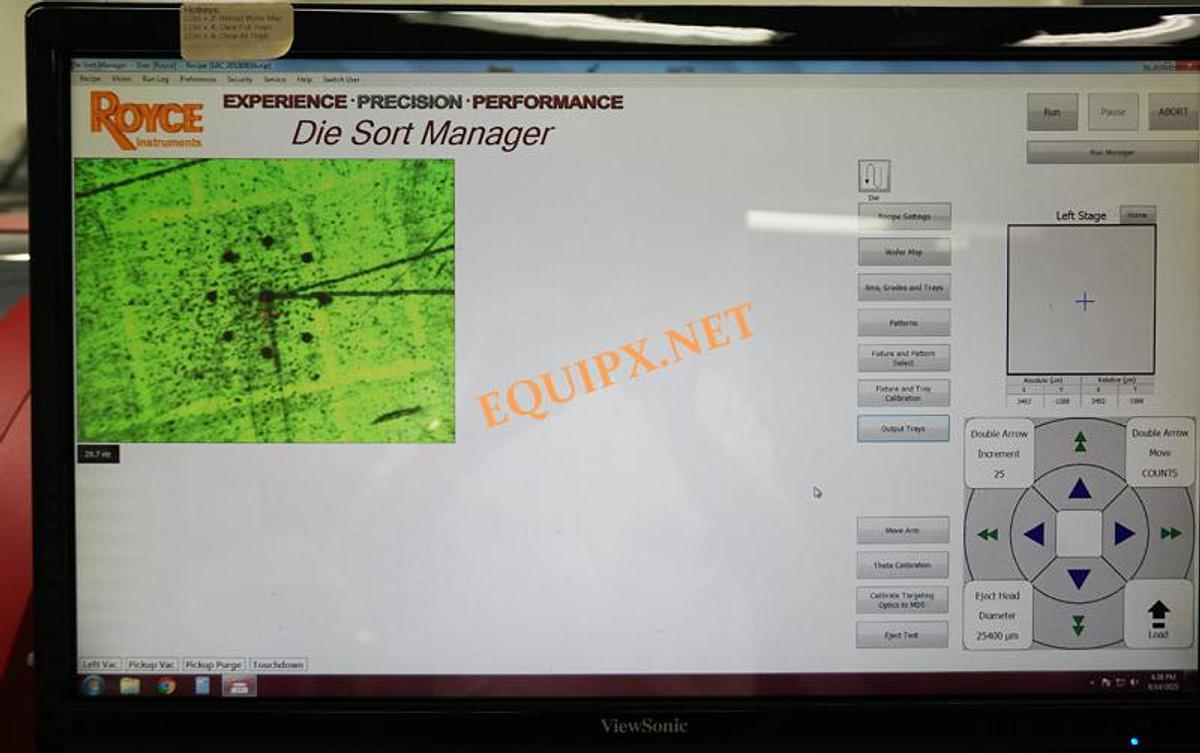

Windows 7 PC with Die Sort Manager Version 4.1.6270.18882

Specifications:

Electronic wafer map

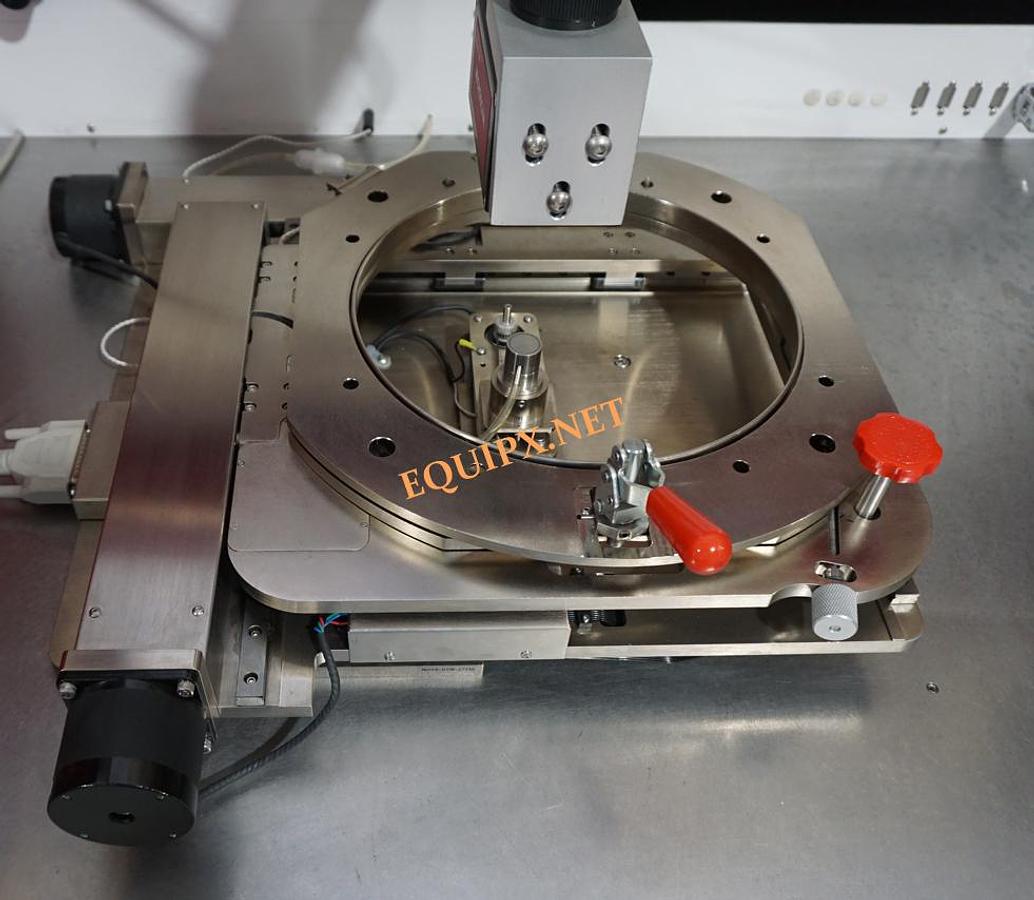

Up to 16 x 2 inches (50mm) waffle pack or Gel-Paks

Quad needle eject head, up to 3 mm eject height

Die size from approx. 0.76 “ 25.6 mm square

Standard soft surface contact vacuum pick up

Microscan DOAL® (Diffuse On-Axis Light) illuminator provides diffuse, uniform illumination for flat specular surfaces. With the coaxial lighting approach, specular surfaces perpendicular to the camera appear bright, while surfaces surfaces which are marked or embossed absorb light and appear dark. By providing greater uniformity than conventional sources, DOALs increase machine vision accuracy and repeatability.

Smart Series Technology: Built-in controller with continuous and high output strobe modes

important when picking die from multi-project wafers, the so called “Pizza Wafers.”

implementation of proven programs at a later date to ensure the reliable and repeatable processing of all die.

die traceability.

Specifications

| Stock Number | 5112 |

| Sort | 0 |